With new products on the horizon here at CockpitCrafters, we thought it’s the perfect time to lift the curtain and give you a behind-the-scenes look at how we design, develop, and launch each of our flight sim accessories. From that first spark of an idea to the moment your order is shipped, every step is carefully crafted with passion, precision, and a good dose of aviation geekery.

✈️ Where Ideas Take Off

Every new CockpitCrafters product begins with an idea – or several. These ideas might come to us mid-flight, while using our own simulators at home, or more often than not, from conversations with our community at events like FS Expo or AERO Friedrichshafen. We listen carefully to what you want and need: products that make flight simulation more immersive, more functional, or just more enjoyable.

We then assess whether this product already exists and if we can improve on it – or if it's something entirely new that doesn’t yet exist but clearly should. Our guiding principle is simple: Would we want this in our own setup? If the answer is yes, the wheels go up and the design process begins.

🎨 Design Process: From Sketch to CAD to Reality

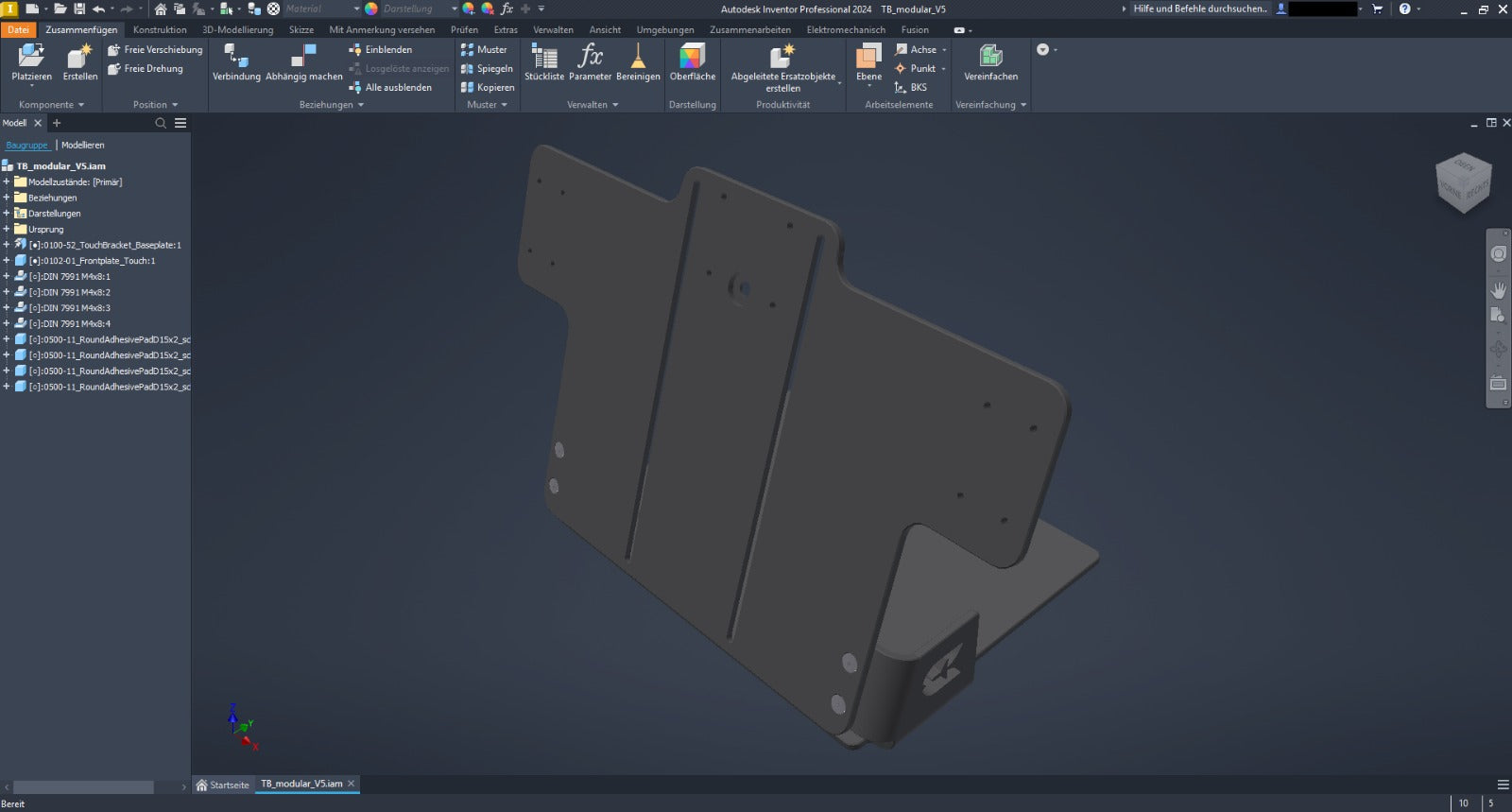

The concept is translated into rough sketches during our brainstorming sessions. Then it’s over to our in-house designer, who brings it to life using CAD software. These models allow us to simulate dimensions, fitting, and interactions before physically producing anything.

Once we're satisfied with the CAD design, we produce the first prototypes using 3D printing. This step allows us to quickly evaluate how the product feels in-hand, how it mounts, and how it holds up in daily simulator use. We iterate – often multiple times – refining ergonomics, functionality, and material choices until we reach a prototype that performs flawlessly.

🔧 Making the Real Product

With a working prototype approved, we move into full product development. That includes selecting production materials, refining surface textures, determining finishes, and evaluating tactile feel – especially if the product is something you'll touch or manipulate frequently.

We work with trusted suppliers to manufacture parts with tight tolerances and high consistency. Samples are rigorously tested, sometimes returned for revisions, until everything meets our standards.

📦 The Art and Science of Packaging

The product is only part of the experience – packaging plays a big role too. We design custom packaging for each product: durable enough to survive international shipping, visually appealing enough to delight on unboxing, and smart enough to protect accessories and components inside.

This stage involves designing internal packaging structures, choosing the right size of seal bags, and creating pictogram-based assembly instructions that are easy to follow in any language. We also design labels and stickers, machine the packaging tooling, and register EAN barcodes so our products are retail-ready.

🔩 Screws, Tools & Accessories – The Small but Mighty Details

We take the same level of care when it comes to the accessories that ship with our products. Screws need to have the correct size, threading, material, and surface coating to ensure durability and usability. If a tool is required for assembly, it must be intuitive and reliable. We source and test these components individually before selecting the best for inclusion.

📚 Assembly & Quality Control

Once every component, screw, label, and instruction booklet is on hand, we move into assembly. This happens in-house, where every unit is checked for quality before packaging begins. Accessories are sorted into labeled seal bags. Final boxes are packed, sealed, and stored in our warehouse, awaiting shipment.

During this step, we also double-check alignment, fitment, and finish. No unit leaves the building unless it meets our internal quality standards.

🚀 Launching the New Product

Creating the product is only half the journey – now we need to get it into your hands.

We prepare promotional material including photos, user manuals, and announcements. We launch across multiple channels: our website, newsletter, and social media, as well as through our trusted partners like Octavi, Aerosoft, and SimInnovations. We also provide early access units to our favorite YouTubers and reviewers, who give their honest feedback and show you what the product is like in action.

You’ll also see our newest gear at exhibitions around Europe and beyond, where we love meeting fellow enthusiasts face-to-face and sharing what’s next.

📦 Your Order: Ready for Departure

Once your order is confirmed, it’s automatically imported from our shop into our internal merchandise planning and control system. An invoice is generated, and our logistics team is notified. From there, one of our team members picks your item, confirms its contents, prints shipping and export labels, and schedules a pickup with our shipping partner.

You receive a tracking number – and your new gear begins its journey from Germany to your simulator, wherever you are in the world.

Whether it’s a simple mounting tool or a high-fidelity cockpit component, every CockpitCrafters product follows this detailed journey – from inspiration and design to testing, assembly, and delivery. It’s a process powered by passion and made for pilots like you.

We can’t wait to show you what’s next.

Share:

FS Conference 2024

Shipping to the USA is back! (Update October 2025)